Turbine Flow Sensor FM110

principle characteristics

The sensor has the common type, the high precision type and the wear-resisting type (the hard alloy) and so on many kinds of forms. The amplifiers come in both normal and flameproof, and the sensor can also be used with the field flow meter (lithium battery power, 1 year replacement battery).

product application

Turbine flow sensor is a kind of precise flow measurement instrument, suitable for measuring low viscosity medium, such as water, diesel, gasoline, etc. It can be used to measure the flow rate and the total amount of the liquid. Widely used in petroleum, chemical, metallurgy, scientific research and other fields of the calculation, control system.

Range table

| Nominal diameter DN(mm) | Flow range(m3/h) | Nominal pressure PN(MPa) | Maximum pressure loss (MPa) | |

|---|---|---|---|---|

| lower limit | Upper limit | |||

| 10 | 0.2 | 1.2 | 6.3 | 0.05 |

| 12 | 0.4 | 4 | ||

| 15 | 0.6 | 6 | ||

| 20 | 0.8 | 8 | ||

| 25 | 1 | 10 | ||

| 32 | 1.5 | 15 | ||

| 40 | 2 | 20 | ||

| 50 | 4 | 40 | 2.5 | 0.035 |

| 65 | 8 | 80 | ||

| 80 | 10 | 100 | ||

| 100 | 20 | 222 | ||

| 125 | 25 | 250 | ||

| 150 | 40 | 400 | 1.6 | 0.025 |

| 200 | 80 | 800 | ||

| 250 | 120 | 1200 | 1.6 | 0.025 |

| 300 | 180 | 1800 | ||

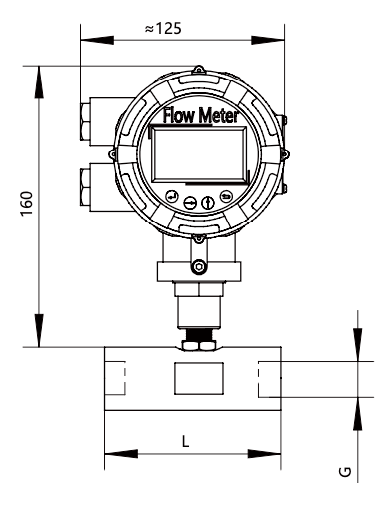

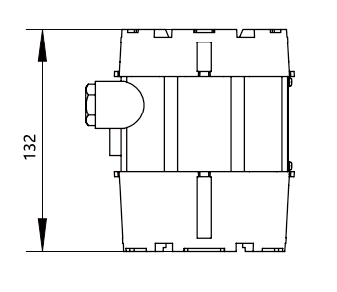

Size chart(mm)

Selection table

| Nominal diameter (mm) | Flange connection (1.6MPa) | External thread | Internal thread | Clamp connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange diameter | Center distance | Pitch | Hole count | Thickness | Body length L (Straight pipe) | Body length L (No straight pipe) | Process connection G | Body length L | Process connection G | Process connection outer diameter | Body length L | |

| 10 | 95 | 65 | 14 | 4 | 14 | 345 | 65 | G1/2 | 80 | 1/2 | 50.5 | 50 |

| 12 | 95 | 65 | 14 | 4 | 14 | 65 | G3/4 | 80 | 1/2 | 50.5 | 50 | |

| 15 | 95 | 65 | 14 | 4 | 14 | 75 | G1(33.2) | 110 | 1/2 | 50.5 | 75 | |

| 20 | 105 | 75 | 14 | 4 | 16 | 85 | G1(33.2) | 115 | 3/4 | 50.5 | 85 | |

| 25 | 115 | 85 | 14 | 4 | 16 | 100 | G1-1/4(41.9) | 140 | 1 | 50.5 | 100 | |

| 32 | 140 | 100 | 18 | 4 | 18 | 120 | G1-1/2(47.8) | 172 | 1-1/4 | 50.5 | 120 | |

| 40 | 150 | 110 | 18 | 4 | 18 | 140 | G2(59.6) | 185 | 1-1/2 | 64 | 140 | |

| 50 | 165 | 125 | 18 | 4 | 20 | 150 | G2-1/2(75.1) | 200 | 2 | 78 | 150 | |

| 65 | 185 | 145 | 18 | 4 | 20 | 175 | G3 | 235 | 2-1/2 | 91 | 175 | |

| 80 | 200 | 160 | 18 | 8 | 20 | 200 | 260 | 3 | 106 | 200 | ||

| 100 | 220 | 180 | 18 | 8 | 22 | 225 | 119 | 220 | ||||

| 125 | 250 | 210 | 18 | 8 | 22 | 250 | ||||||

| 150 | 285 | 240 | 22 | 8 | 24 | 300 | ||||||

| 200 | 340 | 295 | 22 | 12 | 26 | 360 | ||||||

| 250 | 400 | 355 | 26 | 12 | 28 | 400 | ||||||

| 300 | 460 | 410 | 26 | 12 | 32 | 500 | ||||||

Selection table

| FM110- | 015 | A | M | L | - | - | - | Expatiate |

|---|---|---|---|---|---|---|---|---|

| FM110- | FM110 turbine flowmeter | |||||||

| 010 | Measuring caliber DN10 | |||||||

| 010B | Measuring caliber DN10 (with straight pipe) | |||||||

| 012 | Measuring caliber DN12 | |||||||

| 015 | Measuring caliber DN15 | |||||||

| 020 | Measuring caliber DN20 | |||||||

| 025 | Measuring caliber DN25 | |||||||

| 032 | Measuring caliber DN32 | |||||||

| 040 | Measuring caliber DN40 | |||||||

| 050 | Measuring caliber DN50 | |||||||

| 065 | Measuring caliber DN65 | |||||||

| 080 | Measuring caliber DN80 | |||||||

| 100 | Measuring caliber DN100 | |||||||

| 125 | Measuring caliber DN125 | |||||||

| 150 | Measuring caliber DN150 | |||||||

| 200 | Measuring caliber DN200 | |||||||

| 250 | Measuring caliber DN250 | |||||||

| 300 | Measuring caliber DN300 | |||||||

| F | Pulse output (LED display unit) | |||||||

| A | 4~20mA output (LED display unit) | |||||||

| S | 4~20mA + pulse + switching output (LCD display unit) | |||||||

| R | 4~20mA + pulse + switching quantity + communication output (LCD display unit) | |||||||

| C | Battery powered, No output (LCD display unit) | |||||||

| M | External thread connection (for ≤DN50) | |||||||

| K | Internal thread connection | |||||||

| F | Flanged joint | |||||||

| H | Sanitary clamp connection (for ≤DN100) | |||||||

| L | Pressure resistance 16 bar | |||||||

| H | Pressure resistance 250 bar | |||||||

| - | Non-explosion proof | |||||||

| -E | Explosion proof | |||||||

| - | Conventional type (medium temperature ≤100°C) | |||||||

| H | High temperature type (medium temperature ≤130°C) | |||||||

| H1 | Ultra-high temperature type (≤180°C, choose Coil type, install >500mm from power source) | |||||||

| - | Measuring medium: oil (factory default) | |||||||

| S | Measuring medium: water |