Residual chlorine transmitter

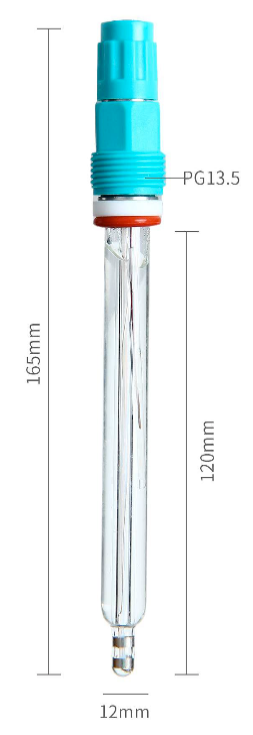

K7700 Constant Voltage Method Chlorine Residual Electrode

The K7700 is a constant-voltage residual chlorine electrode. It features a 99.99% high-purity, large-area dual-platinum ring sensor for precise, stable real-time measurements. Its reference system uses industrial-grade pH electrode technology, significantly enhancing measurement lifespan and stability in water purification scenarios like tap water. It performs well for all media requiring residual chlorine testing and resists long-term high temperatures.

| Measurement Range | 0 - 20 mg/L |

|---|---|

| Temperature Range | 0 - 100 °C |

| Pressure Resistance Range | 0 - 3 Bar, MAX 6 Bar |

| Thermal Compensation Type | NTC2.252K, NTC5K, NTC10K, NTC22K, NTC30K, PT100, PT1000, etc. are available for selection |

| Factory Slope | Superior to 95% |

| Response Time | < 10 seconds |

| Salt Bridge Type | Special porous ceramic core |

| Reference Electrolyte | PCG polymer gel (conventional type) |

| Reference Type | Double salt bridge reference |

| Installation Thread | PG13.5 |

| Shell Material | Glass |

| Insertion Depth | Customizable options include 120/150/225/325/425 mm |

| Cable Connection | Customizable options include S8/S8M/S7/VP8/K8S/K2, etc. |

Features Overview

- Large-area double platinum rings, with stable measurement data

- Strong heat resistance

- Dual liquid contact structure design, long-lasting lifespan

- IP68 level waterproofing

- Precise measurement, fast response time

Expanding Capacity

- The insertion depth of the electrodes can be customized.

- Various cable connection forms can be customized.

- The maximum length of the cable can be extended up to 30 meters.

Application

- Tap water

- Secondary water supply

- Swimming pools

- Equipment for drug addition

- Industrial processes

K7700i True industrial-grade digital free chlorine electrode

The k7700i residual chlorine electrode integrates the transmitter inside the electrode by rethinking the communication among the electrode, end users and process control systems, achieving the integration of the electrode and transmitter. The traditional transmitter functions are replaced by the microprocessor built inside the electrode, which can

| Measurement Range | 0 - 20 mg/L |

|---|---|

| Temperature Range | 0 - 100 °C |

| Pressure Resistance Range | 0 - 3 Bar, MAX 6 Bar |

| Temperature Compensation Type | NTC22 K |

| Factory Slope | Superior to 95% |

| Response Time | < 10 s |

| Salt Bridge Type | Special porous ceramic core |

| Reference Electrolyte | PCG polymer gel (standard type) |

| Reference Type | Dual salt bridge reference |

| Installation Thread | NPT 3/4 |

| Shell Material | POM + glass |

| Insertion Depth | 90 mm (customizable) |

| Cable Connection | Integrated direct connection type |

| Power Supply | 6-30 VDC |

| Communication Method | MODBUS RTU protocol RS485 communication |

Feature Overview

- Standard MODBUS RTU protocol RS485 communication output, with strong resistance to environmental interference

- Special POM material, with strong corrosion resistance

- Large-area double platinum ring processing, ensuring stable measurement data

- Dual liquid connection structure design, with long-lasting lifespan

Expanding Capacity

- The electrode insertion depth can be customized.

- A single multi-hole ceramic core can be upgraded to a double-point or triple-point.

Application

- Tap water

- Secondary water supply

- Swimming pools

- Equipment for drug addition

- Industrial processes

K-FCL3000 Residual Chlorine Transmitter

The K-FCL3500 Residual Chlorine Transmitter adopts a miniaturized design. It can measure residual chlorine and pH value simultaneously, with automatic calculation and compensation functions. Integrating measurement, display, signal transmission, alarm, and communication capabilities, it is equipped with an intelligent menu with switchable Chinese and English, providing users with simple and user-friendly operation. It can also adapt to the harsh requirements of various on-site working conditions

| Screen Parameters | 2.8-inch dot-matrix LCD screen (128*64) |

|---|---|

| Measurement Range | 0.00~20.00 mg/L (residual chlorine); 0.00~14.00 pH |

| Resolution | 0.01 mg/L; 0.01 pH |

| Basic Error | ±0.05 mg/L; ±0.01 pH |

| Temperature Compensation Range | -10~130°C |

| Temperature Compensation Type | PT1000 |

| Two Groups of Relay Control Contacts | 2.5A 230VAC |

| Overall Protection Rating | IP65 |

| Instrument Installation Method | Panel-mounted/Pipeline-mounted/Wall-mounted |

| Mounting Hole Dimensions | 92.5×92.5 mm (positive tolerance) |

| Communication Output | RS485 Modbus RTU (read-write two-way communication) |

| Instrument Power Supply (Optional) | 85~260VAC or 18~36VDC |

| Current Output | Two channels of 4~20 mA (load resistance <500); Accuracy: ±1% FS |

| Instrument Dimensions | (HXWXD) 108×108×132 mm |

| Instrument Operating Environment | Ambient temperature: -10~60°C; Relative humidity: not more than 90% |

Features Overview

- 128*64 dot-matrix LCD display with switchable Chinese and English, IP65 protection rating for stable operation around the clock

- Simple menu design enabling easy and convenient operation, with graphical prompts for an elegant and clear interface

- Adjustable software digital filtering and enhanced hardware anti-interference capability, ensuring more stable measurement and adapting to complex industrial environments

- Globally universal power supply (85~260VAC); customizable DC version (18~36VDC) is also available

- RS-485 digital interface with MODBUS-RTU communication protocol, supporting read-write two-way communication for full remote control of the instrument

- Simultaneous measurement of two parameters (residual chlorine and pH) with automatic calculation and compensation

Application

- Tap water

- Secondary water supply

- Swimming pools Matching with Chemical Dosing Equipment

- Industrial processes