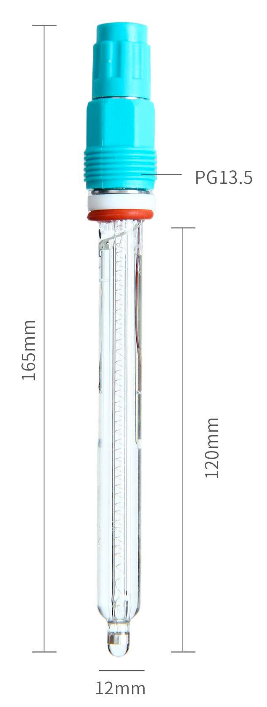

ORP sensor

K4900 Versatile and robust

The K4900 ORP electrode adopts a large-area 99.99% high-purity platinum ring construction, delivering extremely stable measurement potential. Its reference system inherits the reference design from industrial-grade pH electrodes and is interchangeable with similar Mettler products. It meets customer satisfaction requirements in all types of media requiring oxidation-reduction potential (ORP) measurement, while also being capable of withstanding long-term high temperatures.

| Measurement Range | -2000 mV ~ 2000 mV |

|---|---|

| Temperature Range | 0 ~ 130 °C |

| Pressure Resistance Range | 0 ~ 3 Bar, 6 Bar MAX |

| Temperature Compensation Type | NTC2.252K, NTC5K, NTC10K, NTC22K, NTC30K, PT100, PT1000 and other options available |

| Factory Slope | Better than 95% |

| Membrane Resistance | < 100 MΩ |

| Zero Potential | < 10 mV |

| Response Time | < 10 s |

| Salt Bridge Type | Special Porous Ceramic Core |

| Reference Electrolyte | PCG polymer gel (Standard type) |

| Reference Type | Double Salt Bridge Reference |

| Mounting Thread | PG13.5 |

| Housing Material | Glass |

| Insertion Depth: | 120/150/225/325/425 mm, customizable |

| Cable Connection | S8/S8M/S7/VP8/K8S/K2, customizable |

Features Overview

- Wide-range measurement range

- Excellent high-temperature resistance

- Double liquid-junction structure design, ensuring long service life

- IP68 Waterproof Rating

- Large-area platinum ring, enabling stable measurement

- Adaptable to all types of complex working conditions

Expansion Capability

- The electrode insertion depth can be customized

- The single-point porous ceramic core can be upgraded to a double-point or triple-point one

- All types of cable connection configurations can be customized

- The cable length can be extended up to a maximum of 60M

Applications

- Production Processes

- Chemical Processes

- Industrial Wastewater

- Equipment Supporting

K4900i Genuine Industrial-Grade Digital ORP Electrode

The K4900i pH electrode integrates the transmitter into the electrode by rethinking the communication among the electrode, end-users, and process control system operators, thus achieving the integration of the electrode and transmitter. The functions of traditional transmitters are replaced by a microprocessor built into the electrode. This electrode can directly output RS485 signals. Its front-mounted glass electrode differs from conventional electrodes available on the market while those conventional ones are only suitable for environmental water bodies such as surface water, the K4900i pH electrode can perform accurate measurements even in complex industrial sites

| Measurement Range | -2000 mV ~ 2000 mV |

|---|---|

| Temperature Range | 0 ~ 100 °C |

| Pressure Resistance Range | 0 ~ 3 Bar, 6 Bar MAX |

| Temperature Compensation Type | NTC22 K |

| Factory Slope | Better than 95% |

| Response Time | < 10 s |

| Salt Bridge Type | Special Porous Ceramic Core |

| Reference Electrolyte | PCG Polymer Gel (Standard Type) |

| Reference Type | Double Salt Bridge Reference |

| Mounting Thread | NPT 3/4 |

| Housing Material | POM + Glass |

| Insertion Depth | 90 mm (Customizable) |

| Cable Connection | Integrated Direct Connection Type |

| Power Supply Mode | 6-30 VDC |

| Communication Mode | MODBUS RTU Protocol RS485 Communication |

Features Overview

- Standard MODBUS RTU protocol with RS485 communication output, featuring excellent resistance to environmental interference

- Special-grade POM material, providing enhanced corrosion resistance

- Double liquid-junction structure design, ensuring long service life

- IP68 Waterproof Rating

- High measurement accuracy and fast response time

- NPT 3/4 threads allow for direct installation into processes

Expansion Capability

- The electrode insertion depth can be customized

- The single-point porous ceramic core can be upgraded to a double-point or triple-point one

- The cable length can be extended up to a maximum of 100M

Applications

- Wastewater Treatment

- Equipment Supporting

- Swimming Pools

- Surface Water

- Industrial Processes

K1300 pH/ORP Signal Transmission Module

The K1300 pH/ORP Signal Transmission Module integrates electronic circuits and microprocessors into a DIN rail-mounted module housing. It can be used with analog pH or ORP electrodes, featuring measurement, signal transmission, and communication functions, thus flexibly meeting various online pH or ORP monitoring needs. With its compact size, it is easy to integrate and can adapt to the harsh requirements of various on-site working conditions.

| Measurement Range | pH: 0~14.00 pH; ORP: -2000~+2000 mV |

|---|---|

| Temperature Compensation Range | -10~130 °C |

| Resolution | pH: 0.01 pH; ORP: 1 mV |

| Temperature Compensation Type | NTC10k/PT1000 |

| Basic Error | pH: ±0.02 pH; ORP: ±1 mV |

| Power Supply | 18~27 VDC |

| Stability | pH: <0.02 pH/24h; ORP: <2 mV/24h |

| Communication Output | RS485 Modbus RTU |

| Current Output | 4~20 mA (load resistance <500Ω); Accuracy: ±0.01 mA |

| Dimensions | 103 (L) x 85 (H) x 23 (T) mm |

| Installation Method | DIN rail mounting, rail size: 33 mm |

| Instrument Operating Environment | Ambient temperature: -10~60 °C; Relative humidity: not more than 90% |

Features Overview

- RS-485 transmission interface with MODBUS-RTU communication protocol, supporting two-way communication

- Power supply and output isolation design, ensuring electrical safety

- Built-in protection circuit enhances anti-interference capability to adapt to complex environments

- Simple and user-friendly communication protocol that can output more electrode diagnostic information, making it more intelligent

- Low-power design to cope with more application scenarios; internal memory can store calibration and setting information in case of power failure

- Industrial DIN rail mounting, facilitating on-site installation and system integration

- pH value can be calibrated via the instrument's internal buttons, and an optional hand-held operator is available for convenient on-site operation and maintenance

Applications

- Thermal Power

- Chemical Industry

- Chemical Fertilizer

- Desulfurization & Denitrification

- Surface Treatment

- Metallurgy

- Environmental Protection

- Pharmaceutical Industry

- Biochemical Industry

- Food Industry

- Tap Water Supply

- Textile Dyeing & Printing

K-PH5000 pH/ORP Transmitter

The K-PH5000 pH/ORP Transmitter adopts a miniaturized design and can be used with analog pH or ORP electrodes. It integrates measurement, display, signal transmission, alarm, and communication functions, flexibly meeting various online pH or ORP monitoring needs. Equipped with a high-definition LCD screen and an intelligent menu with switchable Chinese and English, it provides users with simple and user-friendly operation, and can adapt to the harsh requirements of various on-site working conditions.

| Screen Parameters | 2.8-inch high-definition monochrome screen (320*240) |

|---|---|

| Measurement Range | pH: 0~14.00 pH; ORP: -2000~+2000 mV |

| Resolution | pH: 0.01 pH; ORP: 1 mV |

| Basic Error | pH: ±0.02 pH; ORP: ±1 mV |

| Automatic/Manual Temperature Compensation Range | -20~150 °C |

| Temperature Compensation Type | NTC10k/PT100/PT1000; NTC22k/NTC2.252k |

| Stability | pH: <0.02 pH/24h; ORP: <2 mV/24h |

| Current Output | 4~20 mA (load resistance <5000); Accuracy: ±0.2% |

| Communication Output | RS485 Modbus RTU |

| Two Groups of Relay Control Contacts | 3A 250VAC, 3A 30VDC |

| Instrument Power Supply (Optional) | 220VAC ±10%; 24VDC |

| Instrument Dimensions | 113.5 × 118 × 136 mm |

| Instrument Installation Method | Panel-mounted / Pipeline-mounted / Wall-mounted |

| Mounting Hole Dimensions | 92 × 92 mm |

| Instrument Operating Environment | Ambient temperature: -10~60 °C; Relative humidity: not more than 90% |

| Overall Protection Rating | IP67 |

Features Overview

- High-definition large screen display, facilitating data reading and operation

- Software digital filtering with strong anti-interference capability

- Intelligent calibration technology, automatically identifying calibration points

- IP67 protection rating for stable operation around the clock

- Supports tag input and various parameter correction functions

Applications

- Thermal Power

- Chemical Industry

- Chemical Fertilizer

- Textile Dyeing & Printing

- Desulfurization & Denitrification

- Surface Treatment

- Metallurgy

- Environmental Protection

- Pharmaceutical Industry

- Biochemical Industry

- Food Industry

- Tap Water Supply