Electromagnetic Flowmeter FM260

Product overview

According to Faraday's principle of electromagnetic induction, when a

conductor passes vertically through magnetic field B, it will induce a

voltage. U In the measurement of the flowmeter, the moving conductor is a

flowing conductive medium, the magnetic field B is emitted from the

direction perpendicular to the flowing medium, and the induced electro-

motive force U on the two electrodes E1 and E2 is directly proportional to

the flow rate V of the medium.

U=K×B×V×D

K- Meter constant

D- Internal probe spacing

After further processing, the induced electromotive force U is converted

into a standard electrical signal output or display

Functional characteristics

- Compact design saves installation space

- Anti-corrosion sensor technology

- All electronic design without viscosity of moving parts

- Automatic temperature compensation

- Pulse output/analog output /RS485 communication optional

- Low pressure loss

- Strong anti-fouling ability

Technical Specifications

- Measuring range: See range table

- Suitable pipe diameter: DN4... DN25 (see selection table)

- Measuring medium: conductive liquid (conductivity > 20uS/cm)

- Accuracy: ≤±0.5% range

- Repeatability: ≤±0.2% range

- Pressure resistance: 16 bar

- Supply voltage: 24±10%Vdc

- Current consumption: ≤80mA

- Electrical protection: reverse polarity protection, short circuit protection

- Output:

- Pulse output: NPN output, pull-up resistor $2\text{K}\Omega$

- Analog output: 4... 20mA, current limit 26mA, load resistance < 250Ω

- Response time: < 100ms

- Ambient temperature: -25... 85 °C

- Medium temperature: -40... 120 No thermal shock (optional high temperature 140°C)

- Materials:

- Electrode: stainless steel 316TI

- Process connection: stainless steel 316TI

- Measuring tube: PEEK

- Seal: EPDM

- Housing: stainless steel 304

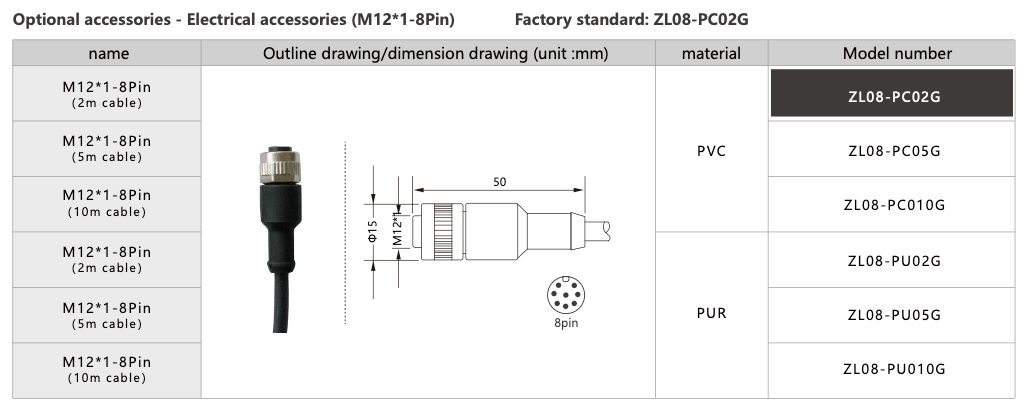

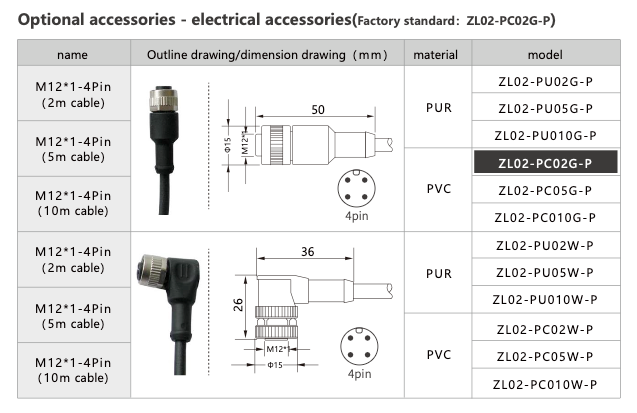

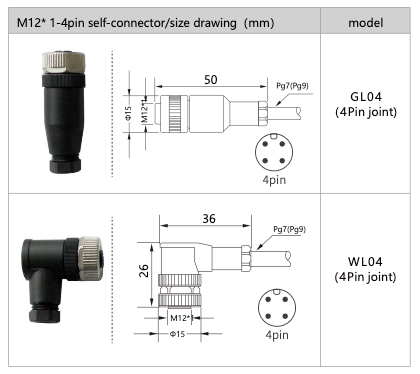

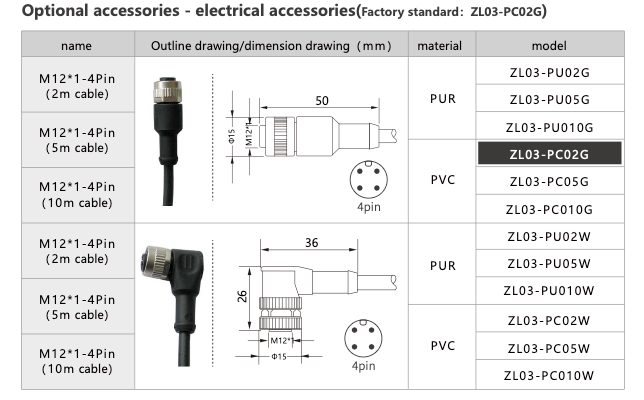

- Electrical connection: M12×1 connector

- Process connection: external thread/internal thread/sanitary chuck can be selected

Wiring diagram

8-core wire

| line | color | Feature |

|---|---|---|

| 2 | BN | power supply(+) |

| 7 | BU | power supply(-) |

| 8 | RD | RS485(A) |

| 4 | YE | RS485(B) |

| 6 | PK | pulse (+) |

| 1 | WH | pulse (-) |

| 3 | GN | electric current (-) |

| 5 | GY | electric current (+) |

5-core wire

| line | color | Feature |

|---|---|---|

| 1 | BN | power supply(+) |

| 3 | BU | power supply(-) |

| 5 | GY | Analog signal (mA) |

| 2 | WH | RS485 (A) |

| 4 | BK | RS485 (B) |

4-core wire

| line | color | Feature |

|---|---|---|

| 1 | BN | power supply(+) |

| 3 | BU | power supply(-) |

| 2 | WH | RS485(A) |

| 4 | BK | RS485(B) |

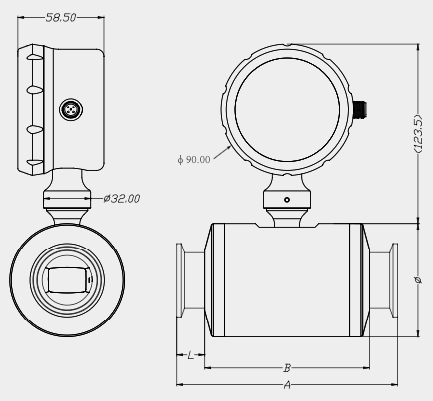

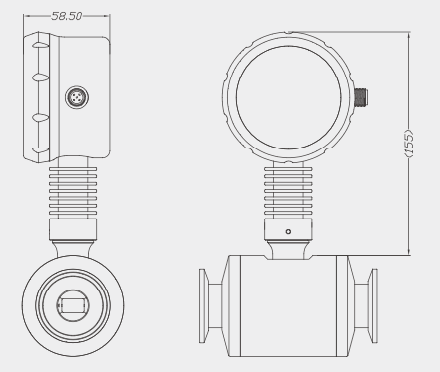

Dimension drawing(mm)

Chuck connection

| Specification and model | Chuck connection | Pipe diameter (DN) | A | B | $\phi$ | Measuring range (L/min) |

|---|---|---|---|---|---|---|

| FM260-H04 | 25.4 Sanitary chuck | 4 | 90 | 60 | 45 | 0.1-10 |

| FM260-H08 | 25.4 Sanitary chuck | 8 | 104 | 74 | 60 | 0.5-25 |

| FM260-H12 | 50.5 Sanitary chuck | 15 | 120 | 90 | 70 | 1-60 |

| FM260-H15 | 50.5 Sanitary chuck | 15 | 120 | 90 | 70 | 3-100 |

| FM260-H25 | 50.5 Sanitary chuck | 25 | 150 | 112 | 78 | 4-200 |

| FM260-H32 | 50.5 Sanitary chuck | 32 | 210 | 150 | 115 | 20-300 |

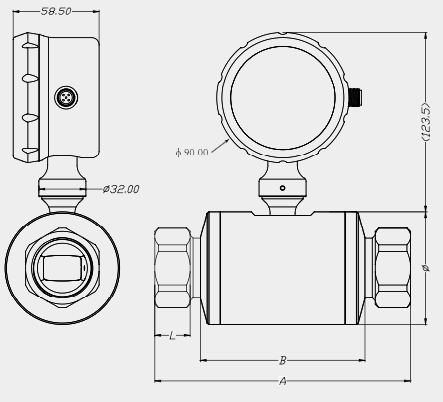

Internal thread connection

| Specification and model | Internal thread connection | Pipe diameter (DN) | A | B | $\phi$ | Effective screw (L) | Measuring range (L/min) |

|---|---|---|---|---|---|---|---|

| FM260-GK04 | G1/4" | 4 | 90 | 60 | 45 | 13 | 0.1-10 |

| FM260-GK08 | G1/2" | 8 | 122 | 74 | 60 | 13 | 0.5-25 |

| FM260-GK12 | G3/4" | 15 | 142 | 90 | 70 | 15 | 1-60 |

| FM260-GK15 | G3/4" | 15 | 142 | 90 | 70 | 15 | 3-100 |

| FM260-GK25 | G1-1/4" | 25 | 174 | 112 | 78 | 20 | 4-200 |

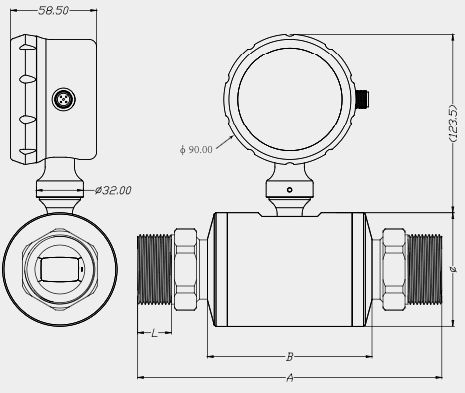

External thread connection

| Specification and model | External thread connection | Pipe diameter (DN) | A | B | $\phi$ | Effective screw (L) | Measuring range (L/min) |

|---|---|---|---|---|---|---|---|

| FM260-GM04 | G1/4" | 4 | 110 | 60 | 45 | 12 | 0.1-10 |

| FM260-GM08 | G1/2" | 8 | 141 | 74 | 60 | 18 | 0.5-25 |

| FM260-GM12 | G1" | 15 | 170 | 90 | 70 | 20 | 1-60 |

| FM260-GM15 | G1" | 15 | 170 | 90 | 70 | 20 | 3-100 |

| FM260-GM25 | G1-1/2" | 25 | 207 | 112 | 78 | 25 | 4-200 |

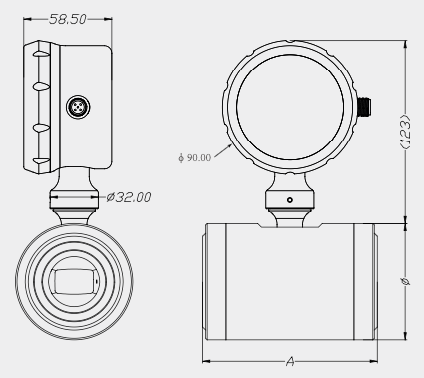

Tie rod flange connection

| Specification and model | pull rod flange | Pipe diameter (DN) | A | $\phi$ | Measuring range (L/min) |

|---|---|---|---|---|---|

| FM260-F04 | DN15 | 4 | 63 | 45 | 0.1-10 |

| FM260-F08 | DN25 | 8 | 80 | 60 | 0.5-25 |

| FM260-F12 | DN32 | 15 | 92 | 70 | 1-60 |

| FM260-F15 | DN32 | 15 | 92 | 70 | 3-100 |

| FM260-F25 | DN32 | 25 | 116 | 78 | 4-200 |

High temperature type(>120°)

Selection list

| FM260 Electromagnetic Flowmeter Model Code | ||||||

|---|---|---|---|---|---|---|

| Position 1 | Position 2 | Position 3 | Position 4 | Position 5 | Position 6 | Instructions (Description) |

| FM 260 - | FM 260 Electromagnetic flowmeter | |||||

| H | Process connection: Chuck connection | |||||

| G K | Process connection: G thread internal teeth | |||||

| G M | Process connection: G thread external teeth | |||||

| F | Process connection: Pull rod flange | |||||

| 04 | Caliber: DN 4 | |||||

| 08 | Caliber: DN 8 | |||||

| 15 | Caliber: DN 15 | |||||

| 25 | Caliber: DN 25 | |||||

| P R | Pulse/Current /RS485 (8 cores) | |||||

| R A | RS485/analog mA (5 cores) | |||||

| R S | RS485 communication (4 cores) | |||||

| - | Medium temperature: -20... 120 °C | |||||

| H 1 | Medium temperature: -20... 140 °C | |||||

| H 2 | Medium temperature: -40... 120 °C | |||||

| H 3 | Medium temperature: -40... 140 °C | |||||

| - | Sealing material: Silicone (-40...120 °C coolant) | |||||

| K | Sealing material: Perfluoroether | |||||

| E | Sealing material: EPDM | |||||

| F | Sealing material: Fluorine rubber (0...120 °C) | |||||

| N | Sealing material: Nitrile rubber | |||||