Electronic flow switch FS230

Principles characteristics

FM230 electromagnetic flowmeter is a main flow meter, composed of two parts of the sensor and the converter, based on Faraday's law of electromagnetic induction work, used to measure conductive liquid or two-phase medium, requiring its conductivity should generally be greater than 25μs/cm(tap water original conductivity of about 25μs/cm), It can be used to measure various acids, alkalis, salt solutions, pulp, pulp and other media, but the media can not contain more ferromagnetic substances and a large number of bubbles.

Product application

Widely used in petroleum, chemical industry, metallurgy, textile, paper, environmental protection, food and other industrial departments and municipal management, water conservancy construction and other fields of fluid measurement.

- The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity

- There are no obstructing parts in the measuring tube, no pressure loss, and low requirements in the straight pipe section

- The sensor can be equipped with a ground electrode to achieve good grounding of the instrument

- With positive/reverse two-way flow measurement function

- The LCD backlight display allows easy reading in direct sunlight or in a dark room

- Converter displays volume flow percentage, actual flow and cumulative flow at the same time

- Mounted on the pipe with a standard (type) ≤90° rotating display improves the visibility of a single type flowmeter

- The converter has the functions of self-diagnosis alarm output, empty load detection alarm output, flow upper and lower limit alarm output, two-stage flow value output

Technical parameters

- Measuring caliber: DN10mm-DN3000mm

- Measuring medium: Conducting liquid, slurry

- Dielectric conductivity:

- Conventional type ≥25μs/cm

- Low conductivity type >5μs/cm

- Measuring accuracy:

- ±0.5% of the indicated value,

- ±0.3% ±0.2% of the optional indicated value

- Measuring range: 150:1 Flow rate setting: 0.1 ~ <15m/s

- Structure form: One body type, divided body type

- Electrode material: Stainless steel 316L, platinum-iridium, Hastelloy, tantalum, titanium

- Electrical connection: M20x1.5 (standard nylon waterproof connector), optional explosion-proof metal connector

- Power supply mode: 220VAC/24VDC

- Running power consumption: ≤15VA

- Lining material: Polyfluoroethylene propylene (FEP), polyurethane rubber

- Shell material:

- Carbon steel (standard),

- stainless steel (non-standard custom)

- Medium temperature: -40°C ~ +180°C (Limited by the temperature resistance characteristics of the lining material)

- Ambient temperature: -25°C ~ +60°C

- Environmental humidity: 5 ~ 100%RH (relative humidity)

- Shell protection grade: Integrated (IP65), Split (IP65/IP68)

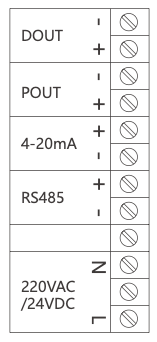

Electrical connection

| identification | implication |

|---|---|

| RS485+ | Communication (485-A) |

| RS485- | Communication (485-B) |

| POUT+ | Pulse/frequency output is positive |

| POUT- | Pulse/frequency output area |

| 4-20mA+ | Current output positive |

| 4-20mA- | Where the current is delivered |

| DOUT+ | Alarm output positive |

| DOUT- | Alarm delivery point |

| N | 220VAC (24VDC) power input |

| L | 220VAC (24VDC) power input |

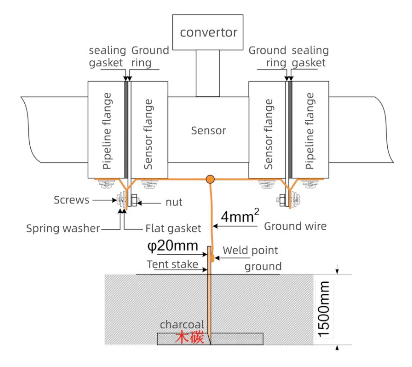

Grounding Mode

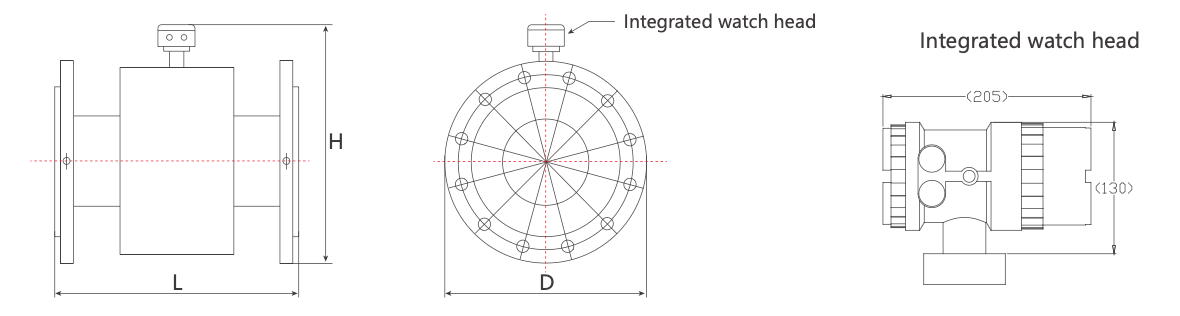

Size drawing(mm)

| Nominal diameter (mm) | Nominal pressure (MPa) | Overall dimension (mm) | Reference weight (kg) | ||

|---|---|---|---|---|---|

| Meter length (including lining) | D | H | |||

| 6 | 4.0 | 200 | 90 | 220 | 6 |

| 10 | 4.0 | 200 | 90 | 220 | 6 |

| 15 | 4.0 | 200 | 95 | 220 | 8 |

| 20 | 4.0 | 200 | 105 | 220 | 10 |

| 25 | 4.0 | 200 | 115 | 223 | 12 |

| 32 | 4.0 | 200 | 140 | 240 | 13 |

| 40 | 4.0 | 200 | 150 | 250 | 14 |

| 50 | 200 | 165 | 263 | 15 | |

| 65 | 200 | 185 | 283 | 18 | |

| 80 | 200 | 200 | 290 | 20 | |

| 100 | 1.6 | 250 | 235 | 318 | 25 |

| 125 | 1.6 | 250 | 270 | 350 | 28 |

| 150 | 1.6 | 300 | 300 | 380 | 30 |

| 200 | 350 | 340 | 430 | 50 | |

| 250 | 450 | 405 | 495 | 70 | |

| 300 | 500 | 460 | 547 | 95 | |

| 350 | 550 | 520 | 602 | 120 | |

| 400 | 600 | 580 | 665 | 140 | |

| 450 | 1.0 | 600 | 640 | 720 | 160 |

| 500 | 1.0 | 600 | 715 | 783 | 200 |

| 600 | 1.0 | 600 | 840 | 897 | 280 |

| 700 | 700 | 895 | 982 | 350 | |

| 800 | 800 | 1015 | 1092 | 400 | |

| 900 | 900 | 1115 | 1192 | 480 | |

| 1000 | 1000 | 1230 | 1299 | 550 | |

| 1200 | 1200 | 1405 | 1488 | 660 | |

| 1400 | 1400 | 1630 | 1700 | 750 | |

| 1600 | 0.6 | 1600 | 1830 | 1924 | 850 |

| 1800 | 0.6 | 1800 | 2045 | 2134 | 980 |

| 2000 | 0.6 | 2000 | 2265 | 2344 | 1200 |

| 2200 | 2200 | 2475 | 2549 | 1600 | |

| 2400 | 2400 | 2685 | 2754 | 2000 | |

| 2600 | 2600 | 2905 | 2964 | 2400 | |

| 2800 | 2800 | 2905 | 3169 | 2700 | |

| 3000 | 3000 | 3315 | 3369 | 2900 | |

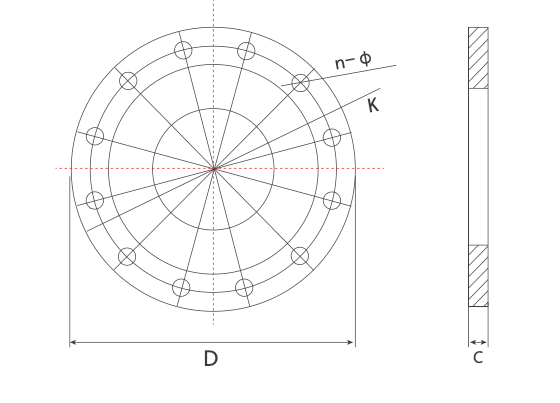

Size drawing(mm)

Connection flange and mounting dimensions

Connection flange implementatiion standard: 4.0MPa(DN6mm~DN50mm) GB/T9119-2000

1.6MPa(DN65mm~DN250mm) JB/T81-94

1.0MPa(DN300mm~DN51000mm) JB/T81-94

0.6MPa(DN1200mm~DN3000mm) JB/T81-94

| Nominal pressure (MPa) | Nominal diameter (mm) | D | K | diameter ($\phi$) | n | c |

|---|---|---|---|---|---|---|

| 4.0 | 6 | 90 | 60 | 14 | 4 | 14 |

| 10 | 90 | 60 | 14 | 4 | 14 | |

| 15 | 95 | 65 | 14 | 4 | 16 | |

| 20 | 105 | 75 | 14 | 4 | 16 | |

| 25 | 115 | 85 | 14 | 4 | 16 | |

| 32 | 135 | 100 | 18 | 4 | 18 | |

| 40 | 145 | 110 | 18 | 4 | 18 | |

| 1.6 | 50 | 160 | 125 | 18 | 4 | 20 |

| 65 | 180 | 145 | 18 | 4 | 24 | |

| 80 | 195 | 160 | 18 | 8 | 24 | |

| 100 | 215 | 180 | 18 | 8 | 26 | |

| 125 | 245 | 210 | 18 | 8 | 28 | |

| 150 | 280 | 240 | 23 | 8 | 28 | |

| 200 | 335 | 295 | 23 | 12 | 30 | |

| 250 | 405 | 355 | 25 | 12 | 32 | |

| 1.0 | 300 | 440 | 400 | 23 | 12 | 28 |

| 350 | 500 | 460 | 23 | 16 | 28 | |

| 400 | 565 | 515 | 25 | 16 | 30 | |

| 450 | 615 | 565 | 25 | 20 | 30 | |

| 500 | 670 | 620 | 25 | 20 | 32 | |

| 600 | 780 | 725 | 30 | 20 | 36 | |

| 700 | 895 | 840 | 30 | 24 | 36 | |

| 800 | 1010 | 950 | 34 | 24 | 38 | |

| 0.6 | 900 | 1110 | 1050 | 34 | 28 | 42 |

| 1000 | 1220 | 1160 | 34 | 28 | 44 | |

| 1200 | 1400 | 1340 | 32 | 32 | 32 | |

| 1400 | 1630 | 1560 | 36 | 32 | 32 | |

| 1600 | 1830 | 1760 | 36 | 40 | 34 | |

| 1800 | 2045 | 1970 | 39 | 44 | 36 | |

| 2000 | 2265 | 2180 | 42 | 48 | 38 | |

| 2200 | 2475 | 2390 | 42 | 52 | 42 | |

| 2400 | 2685 | 2600 | 42 | 56 | 44 | |

| 2600 | 2905 | 2810 | 48 | 60 | 46 | |

| 2800 | 3115 | 3020 | 48 | 64 | 48 | |

| 3000 | 3315 | 3220 | 48 | 68 | 50 |

Unit:m3/h

| caliber(DN) | 1.0 level | 0.5 level | 1.0 level | ||

|---|---|---|---|---|---|

| 0.3m/s | 0.6m/s | 1m/s | 6m/s | 10m/s | |

| 10 | 0.085 | 0.17 | 0.28 | 1.7 | 2.8 |

| 15 | 0.19 | 0.38 | 0.64 | 3.8 | 6.4 |

| 20 | 0.34 | 0.68 | 1.13 | 6.8 | 11.3 |

| 25 | 0.53 | 1.06 | 1.76 | 10.6 | 17.6 |

| 32 | 0.87 | 1.74 | 2.9 | 17.4 | 29 |

| 40 | 1.36 | 2.71 | 4.52 | 27.1 | 45.2 |

| 50 | 2.12 | 4.24 | 7.07 | 42.4 | 70.7 |

| 65 | 3.58 | 7.17 | 11.95 | 71.7 | 119.5 |

| 80 | 5.43 | 10.86 | 18.1 | 108.6 | 181 |

| 100 | 8.48 | 16.96 | 28.27 | 169.6 | 282.7 |

| 125 | 13.25 | 26.5 | 44.18 | 265 | 441.8 |

| 150 | 19.09 | 38.17 | 63.62 | 381.7 | 636.2 |

| 200 | 33.93 | 67.86 | 113.1 | 678.6 | 1131 |

| 250 | 53.01 | 106.03 | 176.71 | 1060.3 | 1767.1 |

| 300 | 76.34 | 152.68 | 254.47 | 1526.8 | 2544.7 |

| 350 | 103.9 | 207.82 | 346.36 | 2078.2 | 3463.6 |

| 400 | 135.72 | 271.43 | 452.39 | 2714.3 | 4523.9 |

| 450 | 171.77 | 343.53 | 572.56 | 3435.3 | 5725.6 |

| 500 | 212.06 | 424.12 | 706.86 | 4241.2 | 7068.6 |

Selection List

| FM230 Series Electromagnetic Flow Sensor Model Code | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FM230 | 050 | S | CR | L | 040 | L | 0 | 0 | AC | 5 | - | - | expatiate (Description) |

| FM230 | FM230 series electromagnetic flow sensor | ||||||||||||

| 050 | DN10—DN1000 | ||||||||||||

| S | Electrode material: **stainless steel** | ||||||||||||

| HB | Electrode material: **Hastelloy B** | ||||||||||||

| HC | Electrode material: **Hastelloy C** | ||||||||||||

| Pt | Electrode material: **platinum** | ||||||||||||

| Ti | Electrode material: **titanium** | ||||||||||||

| Ta | Electrode material: **tantalum** | ||||||||||||

| CR | Lining material: **Neoprene rubber (CR)** | ||||||||||||

| PU | Lining material: **Polyurethane rubber (PU)** | ||||||||||||

| PT | Lining material: **PTFE** | ||||||||||||

| FE | Lining material: **polyperfluorinated ethylene propylene** | ||||||||||||

| L | Shell material: **carbon steel** | ||||||||||||

| S | Case material: **stainless steel** | ||||||||||||

| 040 | **4.0MPa** Applicable caliber: DN10-50 | ||||||||||||

| 016 | **1.6MPa** Applicable caliber: DN10-150 | ||||||||||||

| 010 | **1.0MPa** Applicable caliber: DN65-1000 | ||||||||||||

| 006 | **0.6MPa** Applicable diameter: DN1100-2000 | ||||||||||||

| 0025 | **0.25MPa** Applicable caliber: DN2200 | ||||||||||||

| L | Operating temperature: **<= 70C** | ||||||||||||

| H | Operating temperature: **<= 120C** | ||||||||||||

| 0 | **no** RS485 communication interface | ||||||||||||

| 1 | **RS485 communication interface** | ||||||||||||

| AC | **220VAC** power supply | ||||||||||||

| DC | **24VDC** power supply | ||||||||||||

| 5 | Protection class: **IP65** | ||||||||||||

| 8 | Protection level: **IP68** | ||||||||||||

| - | Converter type: **all-in-one** | ||||||||||||

| F | Converter type: **Split type** | ||||||||||||

| 1 | Install matching flanges: **None** | ||||||||||||

| 1 | Install matching flanges: **Yes** | ||||||||||||

| no | Standard ground ring: **no** | ||||||||||||

| T | Standard ground ring: **T** | ||||||||||||

| - | Conventional type: **dielectric conductivity >= 25$\mu$s/cm** | ||||||||||||

| D | Low conductivity type: **dielectric conductivity >= 5$\mu$s/cm** | ||||||||||||

Installation

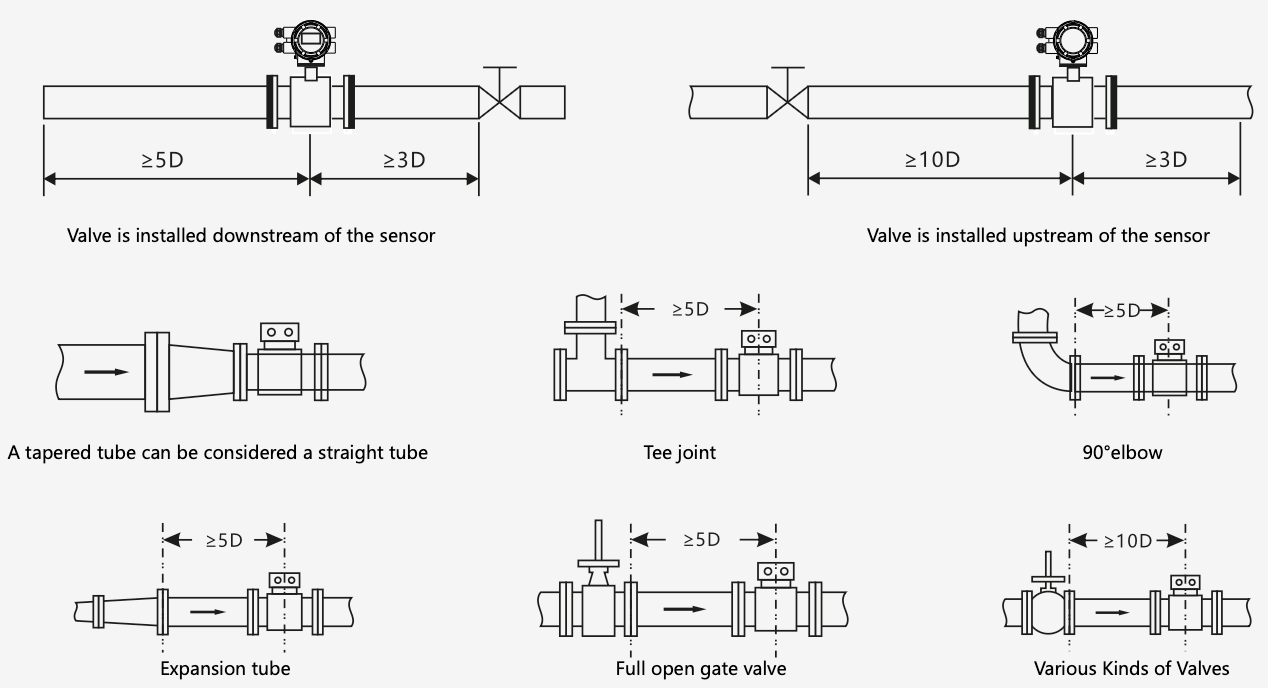

Straight pipe length requirements

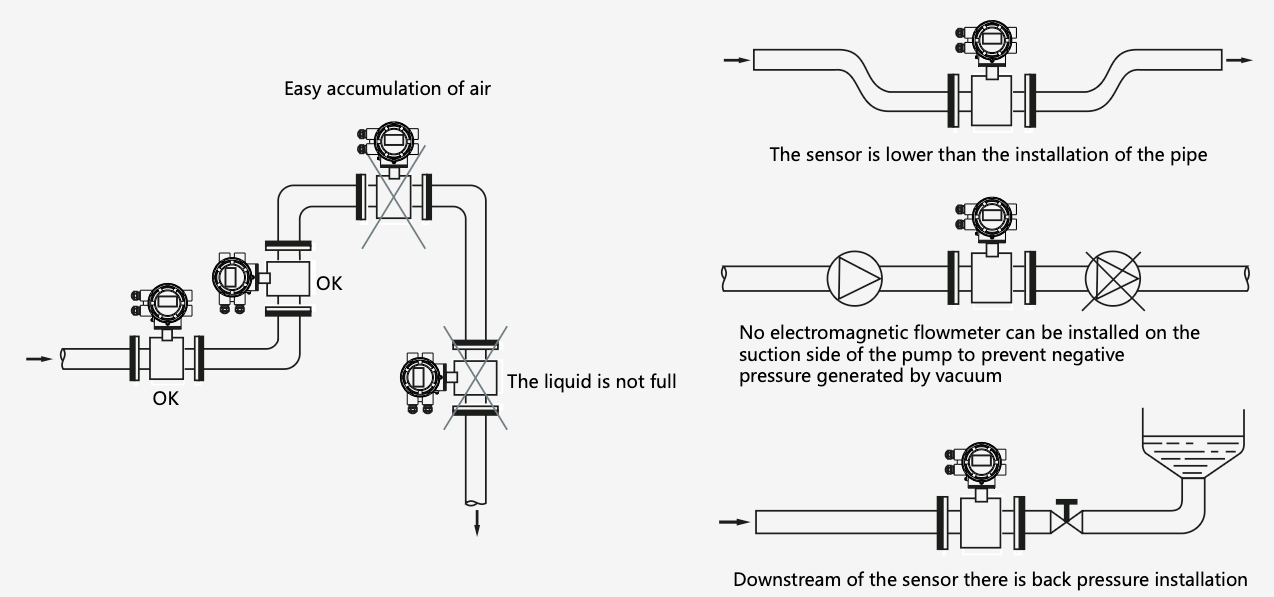

Recommended installation location

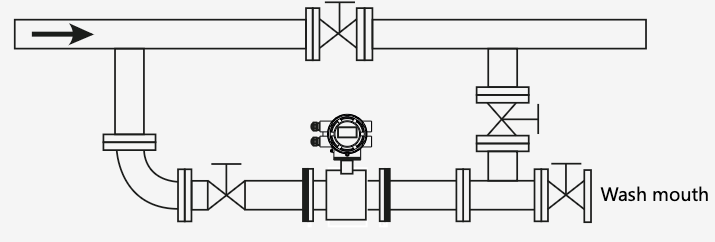

Easy to clean pipe connections

If the pipeline to be cleaned cannot be stopped, the side channel must be installed. To keep the system running while the equipment is being cleaned.