Pressure transducer PM800

Principle and Characteristics

The PM800 pressure transmitter adopts the pressure sensor with isolated diaphragm as the signal measuring element, and through the computer automatic detection and laser resistance adjustment process, the zero point and sensitivity temperature compensation of a wide temperature range are carried out. The pressure of the measured medium directly ACTS on the diaphragm of the sensor, causing the diaphragm to produce a small displacement proportional to the pressure of the medium. After the displacement is detected by the electronic circuit, the displacement is converted into a standard industrial measurement signal corresponding to the pressure. The sensor has good stability and high reliability.

- asic and surface packaging technology

- strong metal housing, suitable for harsh working conditions

- adopt 316L stainless steel diaphragm

- displays multiple units to choose from

product application

It is widely used in petroleum, chemical industry, electric power, metallurgy, pharmaceutical, food and other industrial fields

Technical parameters

- measurement range: -100 kpa... 100 mpa

- accuracy grade: 0.5%FS,0.2%FS

- operating voltage: 12... 36 VDC

- output signal: 4... 20 ma, 0... 10 v, HART

- Temperature impact: < ±0.02%FS/K

- response time: < 5ms

- Cardiac load resistance: 1 k or less Ω

- Response time: < 100ms (10...90%FS)

- Measurement hysteresis: ≤±0.01% full range

- stability: < 0.01%/ year

- medium temperature: -30... 80 ℃... 400 ℃

- ambient temperature: -30... 85 ℃

- Ambient temperature: -30... 85 °C

- protection level: IP65

- Shell information: cast aluminum

Range code

| Standard range | Gage pressure code | Absolute pressure code |

|---|---|---|

| 0...50m bar | B005 | A005 |

| 0...100m bar | B01 | A01 |

| 0...350m bar | B035 | A035 |

| 0...600m bar | B06 | A06 |

| 0...1 bar | B1 | A1 |

| 0...2 bar | B2 | A2 |

| 0...6 bar | B6 | A6 |

| 0...10 bar | B10 | A10 |

| 0...25 bar | B25 | A25 |

| Standard range | Gage pressure code |

|---|---|

| 0...60 bar | B60 |

| 0...100 bar | B100 |

| 0...160 bar | B160 |

| 0...250 bar | B250 |

| 0...400 bar | B400 |

| 0...600 bar | B600 |

| 0...1000 bar | B1000 |

| 0...1500 bar | B1500 |

| 0...2500 bar | B2500 |

| Standard range | Range of code |

|---|---|

| -10...10KPa | F10 |

| -50...50KPa | F50 |

| -100...100KPa | F100 |

| -100...0KPa | F110 |

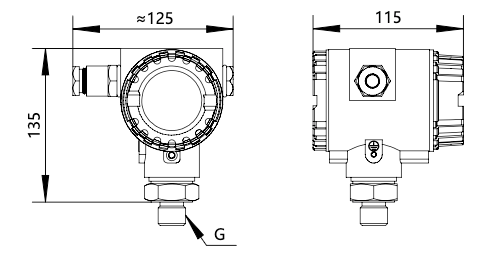

Size chart(mm)

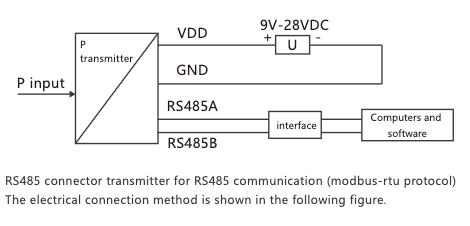

HART communication figure

Selection table

| PM242- | B | ... | A | 5 | M20M | 1 | G | E | detailed |

|---|---|---|---|---|---|---|---|---|---|

| PM800 | PM800 Pressure transducer | ||||||||

| B | Gage pressure | ||||||||

| A | Absolute pressure | ||||||||

| ... | Range (parameter range table) | ||||||||

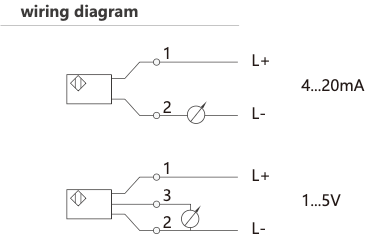

| A | 4...20mA | ||||||||

| AH | 4...20mA+HART | ||||||||

| V05 | 0...5V | ||||||||

| V15 | 1...5V | ||||||||

| V010 | 0...10V | ||||||||

| V110 | 1...10V | ||||||||

| R | RS485 | ||||||||

| 5 | 0.5%FS | ||||||||

| 2 | 0.2%FS | ||||||||

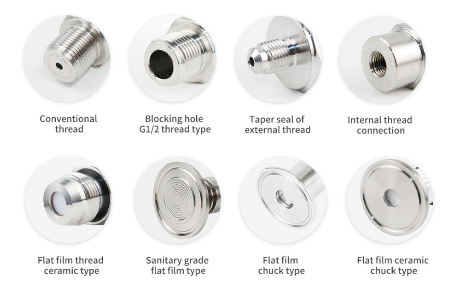

| M20M | M20*1.5 External thread | ||||||||

| G14M | G1/4 External thread | ||||||||

| G12M | G1/2 External thread | ||||||||

| G14K | G1/4 Internal thread | ||||||||

| H50T | Ceramic flat film type: 1.5 "chuck (OD 50.5mm) | ||||||||

| M22T | Ceramic flat film type: M22*1.5 external thread | ||||||||

| H50K | Oil-filled metal flat film type: 1.5 "chuck (OD 50.5mm) sanitary grade | ||||||||

| H50F | Oil-filled metal flat film type: 1.5 "chuck (OD 50.5mm) non-sanitary grade | ||||||||

| M20P | Oil-filled metal flat film type: M20*1.5 external thread | ||||||||

| M22P | Oil-filled metal flat film type: M22*1.5 external thread | ||||||||

| 0 | No display | ||||||||

| 1 | LCD display | ||||||||

| G | Cable gran head | ||||||||

| M20K | Electrical interface:M20*1.5 Internal thread | ||||||||

| G12K | Electrical interface:G1/2 Internal thread | ||||||||

| N12K | Electrical interface:NPT1/2 Internal thread | ||||||||

| E | explosion-proof(ExdIIC T6) | ||||||||

| S | No explosion-proof |